|

|

|

|

Home

Systems Engineering Subsea Control Systems Software Development Products and Applications

Tech Info

Contacts & Key Personnel |

OPC Simulation Server

Introduction

The OPC Simulation Server allows the user to define an OPC tag database using a comma separated (CSV) file, and to simulate a process by changing tag values. The Simulation Server provides two ways of simulating data:

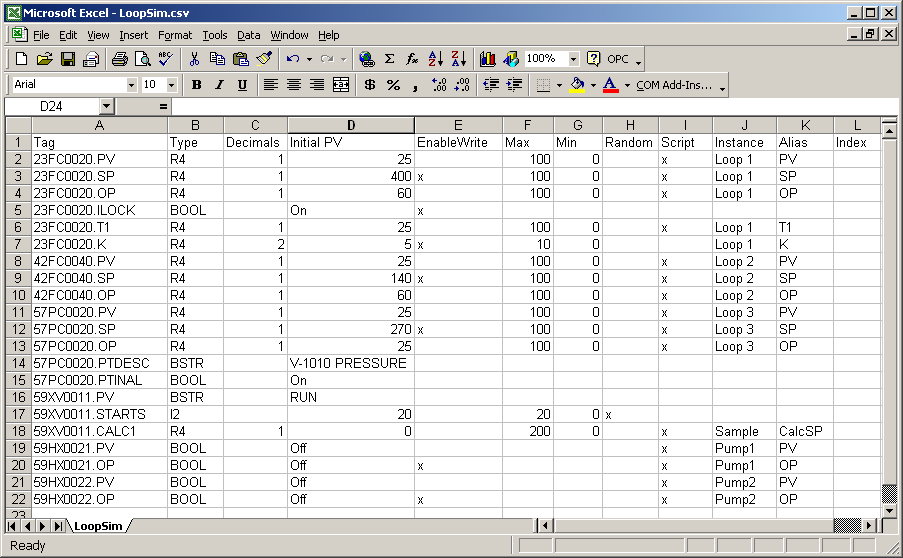

An overall master switch for the simulation is turned on or off using the Simulate dropdown from the Options menu. Configuration The OpcSim.INI file is the main configuration file, a sample of which is shown below: [OPC Simulation Server] LicenseKey=Demo ActiveConfig = 2 [Config 1] Database=TpnServer.csv Simulate=True Scripts=0 [Config 2] Database=Loopsim.csv Simulate=True Scripts=1 Script1=Scripts\LoopSim.vbs Main1=LoopSim [Config 3] Database=ZCalc.csv Simulate=True Scripts=0 [Config 4] Database=WellTest.csv Simulate=True Scripts=1 Script1=Scripts\WellTest.vbs ScriptExecInterval1 = 5 Main1=WellTest License Key ActiveConfig [Config N] Database Database=ZCalc.csv A typical CSV file is shown below: |

|

Simulate The simulation switch can be set on from the main menu of the OPC Sim Server. Scripts ScriptX (X=1,2,3...) Script1=Scripts\LoopSim.vbs Script2=Scripts\PlantSim.vbs MainX (X=1,2,3...) ScriptExecIntervalX (X=1,2,3...) Operation Startup Simulation

The OPC values can be set manually by simply typing in a new value. Individual items may be given a Bad status by ticking the Bad checkbox. OPC Writes Note that this requirement to enable writes only applies to the OPC interface - it is always possible to manually enter a value into the OPC server. Scripting The script can reference the OPC Server tag database, through the following properties of the Sim object:

Option Explicit

'--------------

Sub LoopSim()

'--------------

' Calling a subroutine, and using an Alias

' ----------------------------------------

Sim.TagVal("23FC0020.PV") = 0.6*Sim.TagVal("23FC0020.PV") + 0.4*(Sim.TagVal("23FC0020.OP")) + Sim.Rand

call PID("Loop 1")

End Sub

'---------------

Sub PID(strLoop)

'---------------

' A very crude PID controller

' In fact it is really just using a bit of integral action

dim rError

rError = 0.01*(Sim.AliasVal(strLoop,"SP") - Sim.AliasVal(strLoop,"PV"))

dim rOpCalc, K

K = Sim.AliasVal(strLoop,"K")

rOpCalc = Sim.AliasVal(strLoop,"OP") + Csng(K*rError)

if rOpCalc > 100 then

rOpCalc = 100

elseif rOpCalc < 0 then

rOpCalc = 0

end if

Sim.AliasVal(strLoop,"OP") = rOpCalc

End Sub

Download Purchase a License

Norwegian Customers Only Includes 25% Norwegian MVA

|